21 May Food Engineering Magazine OEE Case Study Article: Pepsi Adopts Real-Time Digital Technology Tool for a ‘Quick-Win’

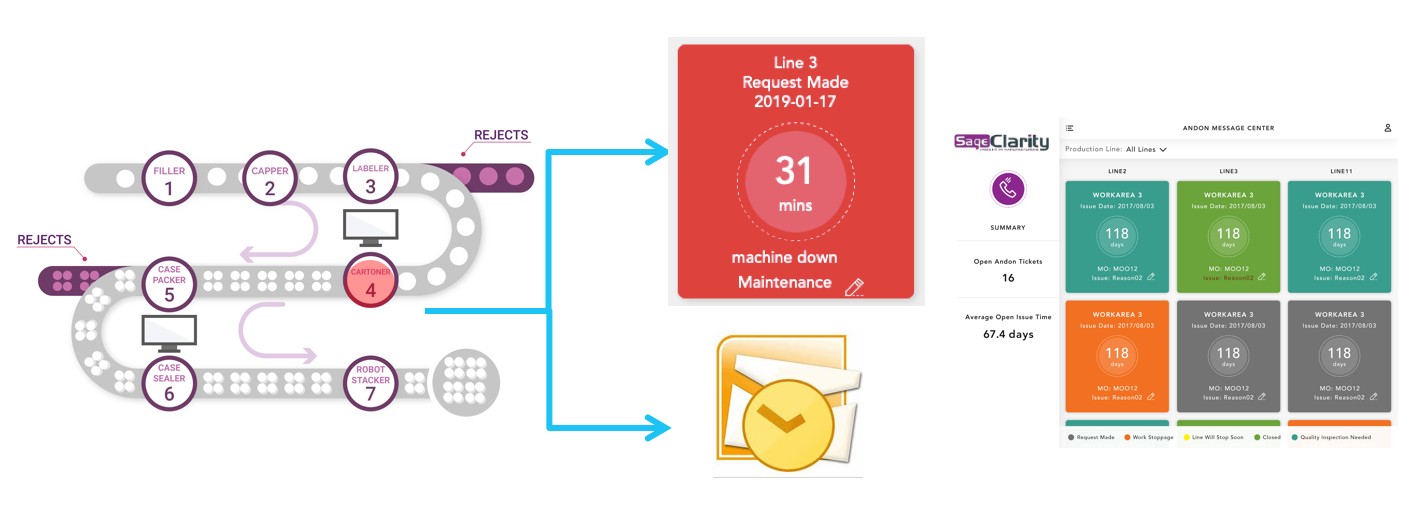

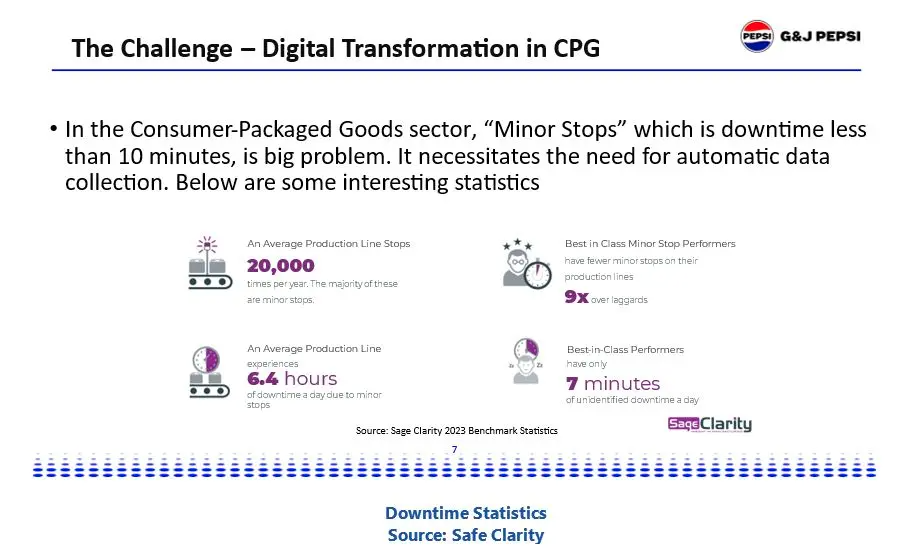

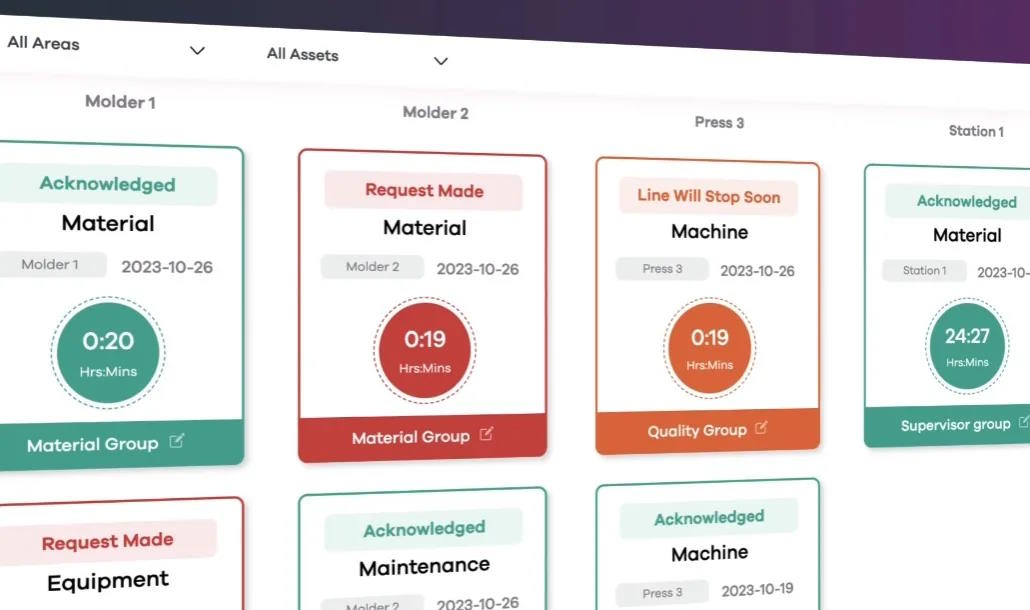

The following is an excerpt from Food Engineering Magazine's OEE case study article authored by Grant Gerke spotlights G&J Pepsi and their use ABLE & One View accelerator application suite for quick wins. The article spotlights how G&J Pepsi unlocked real-time data to access crucial...