24 Apr Sage Clarity’s Digital Accelerator Apps for MES

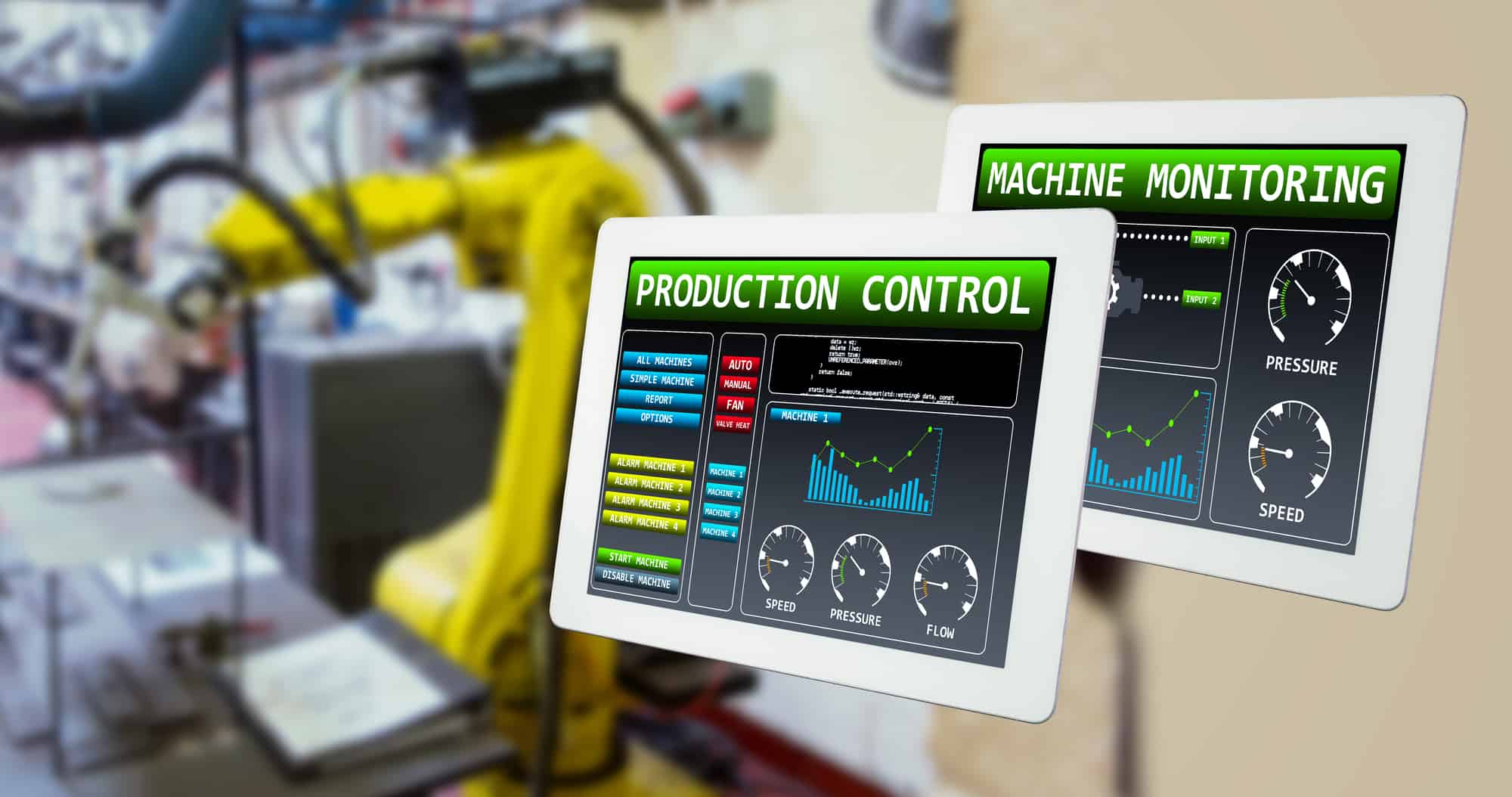

In today’s fast-paced manufacturing world, making informed decisions based on accurate data is critical for success. Sage Clarity’s Digital Accelerator Apps collect and present real-time production data from both machines and operators. This allows manufacturing managers and engineers to monitor and schedule production efficiently, improving cycle times, overall equipment effectiveness, and plant productivity. The Digital Accelerator Apps can be used individually to enhance and supercharge MES deployments or collectively for Lightweight MES. With Sage Clarity’s Digital Accelerator Suite of Apps, more uptime and better cycle times translate to increased reliability, higher-quality products, and, ultimately, higher profits.

Sage Clarity’s Digital Accelerator Apps Enable Real-time Production Monitoring

The Industrial Internet of Things (IIoT) has helped bring manufacturing into the 21st century by enabling the collection and analysis of vast amounts of data directly from machines on the factory floor. However, effectively utilizing this data is vital to making informed decisions and driving continuous improvement.

Sage Clarity’s Digital Accelerator Apps ensure the accuracy of the data collected and feed real-time production metrics and analytics back to managers and engineers. This stream of accurate data empowers them to react to changes in production and make better decisions that keep the factory agile and responsive. Here are some of the tangible production monitoring benefits manufacturers enjoy when they rely on Sage Clarity’s solutions:

Improving Cycle Times and Overall Equipment Effectiveness

In the competitive manufacturing world, it’s essential to constantly strive for improved efficiency and higher production levels. Sage Clarity’s software suite not only provides the tools for monitoring and scheduling but also actively aids in improving cycle times and overall equipment effectiveness (OEE). Using real-time data from machines and operators, critical areas for improvement can be identified and addressed, resulting in better uptime and cycle times. Ultimately, this leads to higher levels of productivity and more reliable manufacturing processes.

Increased Plant Productivity and Reliability

Optimizing production processes and resources isn’t just about increasing output; it’s also about ensuring that the products produced are of the highest quality. Sage Clarity focuses on providing the insights needed to improve reliability and quality across the entire manufacturing process. By monitoring key production metrics such as machine uptime, cycle times, scrap rates, and more, the system helps identify areas where improvements can be made. More effective processes, reduced waste, and fewer unplanned downtime periods result in better products and happier customers.

[optin-monster-inline slug=”qloggraxd3payfghmxer”]

Optimizing Capital Expenditures and Financial Decision Making

Sage Clarity’s Digital Accelerator Suite of Apps optimize capital expenditures by providing real-time production metrics that allow for better decision-making and improving key performance indicators (KPIs) such as OEE, reliability, and cycle times. By investing in these technologies, manufacturers can make significant strides in their efforts to improve profitability and remain competitive in a continuously evolving market.

The ability to make data-driven decisions is essential for success in today’s manufacturing environment. Sage Clarity’s MES Digital Accelerator Apps provide the tools and insights necessary to harness the power of real-time metrics, enabling manufacturing managers and engineers to optimize production processes and improve overall equipment effectiveness and plant productivity. With these powerful tools at their disposal, manufacturers can remain competitive and thrive in a rapidly changing industry, ultimately leading to better products, higher quality, and increased profits.

Sage Clarity’s Digital Accelerator Apps Provide Detailed Asset Insights for Rapid Decision-making.

Sage Clarity’s Digital Accelerator Apps provide advanced real-time analytics paving the way for rapid, strategic decision-making in today’s competitive manufacturing landscape. Sage Clarity’s cutting-edge solution enables you to optimize asset performance. Here’s how:

- HolisticApproach to Asset Monitoring and Optimization

Sage Clarity’s Digital Accelerator Suite of Apps work together as a comprehensive solution for asset monitoring and optimization, covering all aspects of a manufacturing enterprise. From real-time, web-based scorecards and dashboards for analyzing and tracking asset usage to advanced analytics that reveal patterns and correlations, Sage Clarity’s system offers a holistic view of your plant’s assets. Now, identifying inefficiencies and areas for improvement has never been easier, enabling you to proactively optimize resources and reduce your costs.

- Adaptability to Diverse Manufacturing Operations

One of the key strengths of Sage Clarity’s Digital Accelerator Suite of Apps is found in their adaptability to a wide range of manufacturing processes and operations. Whether you’re managing a simple assembly line or a complex production process, the system effortlessly caters to your specific needs. With features and integration capabilities designed to work in a layered way atop existing systems, the apps ensure your plant has an effective monitoring solution in place, regardless of your operation’s size, scale, or complexity.

Sage Clarity Technology Across the Factory Floor

Sage Clarity’s Digital Accelerator Suite of Apps offer a comprehensive solution to streamline your factory floor management and decision-making process. This innovative system integrates ABLE, Next-Gen Andon, OneView, and an array of other tools within its user-friendly app, putting all the valuable data at your fingertips:

- Next-Gen Andon for Intelligent Messaging

Sage Clarity’s Next-Gen Andon system is a vital component of the Digital Accelerator Suite of Apps that aids in improving manufacturing Key Performance Indicators (KPIs). Utilizing the latest alerting technology, it communicates through email, SMS, HMIs, and plant floor terminals to keep you well-informed about the production status in real-time. Automated and operator-created alerts enable production teams to stay ahead of any potential issues, maintaining the production flow and minimizing downtime or inefficiencies. Its not just about bringing attention to an issue, but the ability to track the response time, recovery time and overall resolution of the issue.

- OneView for Purpose Built MES Reporting

To accurately monitor your factory’s efficiency, Sage Clarity presents the OneView app, a powerful tool that enables you to track individual production lines, plants, or entire enterprises. OneView effectively centralizes and simplifies data management by serving as an “atomic clock” – a single source of truth for production metrics for everyone on the factory floor. This feature allows for effective comparison and analysis of production data, facilitating informed decisions by factory managers and engineers.

- Comprehensive Data Analysis with ABLE data collection

Data is king in the current manufacturing landscape, and Sage Clarity’s ABLE apps recognize the importance of reliable, accessible data management. Harnessing the power of advanced data collection, it processes the data collected from various aspects of the factory floor, unveiling essential insights regarding production patterns, resource usage, and operator performance. Comprehensive data analysis enables factory managers to make proactive decisions to optimize operations, address inefficiencies, and enhance overall profitability. ABLE includes unique functionality such as DNA charts, KPI heatmaps and Digital Data Replay.

- Integration and Customization

Sage Clarity’s Digital Accelerator Suite of Apps are designed with flexibility and adaptability in mind, making it suitable for a wide range of industries and manufacturing facilities. Moreover, the system can be easily integrated into your current factory infrastructure with other systems such as Epicor, Rockwell, Aveva and other MES systems, allowing you to maintain your preferred system while reaping the benefits of Sage Clarity’s advanced tools. In addition, customization options ensure that the MES Ecosystem aligns seamlessly with your organization’s unique needs, providing tailored solutions for your manufacturing environment.

Optimize Efficiencies With Sage Clarity’s All-in-One Digital Accelerator Apps

In a competitive and rapidly changing manufacturing landscape, the implementation of advanced tools and systems is crucial to stay ahead of the curve. Sage Clarity’s MES Ecosystem Apps provides the ideal solution for thriving in this environment by enabling seamless data management, effective communication, and comprehensive analysis of crucial manufacturing metrics.

By embracing the power of Sage Clarity’s MES Digital Accelerator Suite and accessing it through its easy-to-use apps, you can efficiently enhance your manufacturing operations, streamline decision-making processes, and drive your organization towards continuous improvement and long-term success.