Our real-time manufacturing analytics platform will turbocharge your operation.

Consumer’s tastes are rapidly changing, and with that more flexibility is required than ever for the food and beverage industry to keep up with changing demand and be able to adapt with new trends.

Operational Effectiveness is a key element to ensure food safety, quality, and ensure you’re product holds up to your brand standards. In our era, this often needs to happen at a global scare.

Sage Clarity solutions allow your operation to avoid out-of-stock situations, manage quality of your product, and improve efficiency to help your products to market more rapidly.

Our Solutions

Closed Loop Planning & Execution

Track orders in real-time with feedback performance information sent to your ERP when the runs are complete.

Insights from Food & Beverage Experts

How we improved plant performance by engaging staff

“Anybody under the age of 20 has a very different view of data and information than people in the current workforce,” observes John Oskin, founder and CEO of Sage Clarity Systems, Chicago. The presentation of and access to data from the corner office to the shop floor is changing, though “the future is not about top-down vs. bottom-up initiatives,” he says. Instead, it is about engagement and involvement in achieving improvements that can be financially quantified.

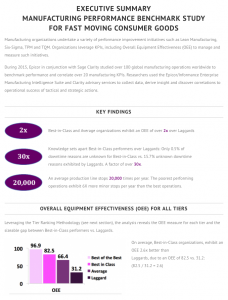

2017 Benchmarks Study: Manufacturing performance OEE for fast moving consumer goods.

Manufacturing organizations undertake a variety of performance improvement initiatives such as Lean Manufacturing, Six-Sigma, TPM and TQM. Organizations leverage KPIs, including Overall Equipment Effectiveness (OEE) to manage and measure such initiatives.

Sage Clarity studied global manufacturing operations worldwide to benchmark performance and correlate over 20 manufacturing KPIs. Researchers used the Epicor/Informance Enterprise Manufacturing Intelligence Suite and Clarity advisory services to collect data, derive insight and discover correlations to operational success of tactical and strategic actions.

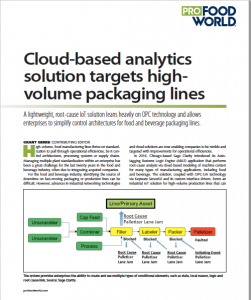

How Our IIoT solution for enterprises simplifies control architectures across packaging lines.

For the manufacturing industry, identifying the source of downtime on fast-moving packaging or production lines can be difficult. However, advances in industrial networking technologies and cloud solutions are now enabling companies to be nimble and targeted with improvements for operational efficiencies. Our Autotagging Business Logic Engine (ABLE) application performs root-cause analysis via cloud-based modeling of machine centers

for many types of manufacturing applications.