Benefits of Next-Gen Andon

- Improved communication between operators and engineers with combined system of digital signage on the production floor, Andon lights, and email alerts

- Better continuous improvement opportunities

- Reduce downtime to boost OEE and quality improvements

Features:

- Role-based alarms notify the right person at the right time based on alarm type and location

- Integrate with your existing Andon lights system

- Integrate with your MES or ERP systems

- Digital alerts on operator HMIs and factory floor displays

- Built-in reporting to track alerts over time and response time

- Integrate machine related and non-machine related issues

“Andon” – The Definition

What is an Andon System?

Andon (アンドン, あんどん, 行灯) is a manufacturing term referring to a system to notify management, maintenance, and other workers of a quality or process problem. The centerpiece is a signboard incorporating signal lights to indicate which workstation has the problem. The alert can be activated manually by a worker using a pullcord or button or may be activated automatically by the production equipment itself. The system may include a means to stop production so the issue can be corrected. Some modern alert systems incorporate audio alarms, text, or other displays.

An Andon system is one of the principal elements of the Jidoka Quality-Control method pioneered by Toyota as part of the Toyota Production System and therefore now part of the Lean approach. It gives the worker the ability to stop production when a defect is found, and immediately call for assistance. Common reasons for manual activation of the Andon are part shortage, defect created or found, tool malfunction, or the existence of a safety problem. Work is stopped until a solution has been found. The alerts may be logged to a database so that they can be studied as part of a continuous-improvement program.

The system typically indicates where the alert was generated and may also provide a description of the trouble. Modern Andon systems can include text, graphics, or audio elements. Audio alerts may be done with coded tones, music with different tunes corresponding to the various alerts, or pre-recorded verbal messages. Usage of the word originated within Japanese manufacturing companies, and in English is a loanword from a Japanese word for a paper lantern.

Andon systems are often used as part of a Lean Manufacturing initiative. Lean practitioners like the simplicity and accountability that comes with Andon. Andon can be deployed as a simple system using pull cords, Andon lights or Andon signals. More advanced systems include Andon Alerts, Andon Display Boards and become a repository for tracking issues.

…Evolution of Andon Systems

Toyota created the Andon concept as a tool for assembly line operators to notify other workers and supervisors of an immediate production issue. When a defect was spotted or created, an operator would pull an overhead cord to stop the assembly line and trigger a light or sound. This would signal over someone to help resolve the problem. The term Jidoka “building quality in” motivated Toyota to go through such lengths for quality assurance.

Jidoka, Building Quality into Andon.

Other companies have modified and added to the Andon concept to expand its relevance beyond the automotive sector. Companies have developed systems that allow operators to send signals specific to certain malfunctions. They have also enhanced visual displays to communicate to other operators and supervisors what and where the problem is. Sage Clarity builds on these innovations to bring customers a superior Andon notification system and help them incorporate “Jidoka” into their plants.

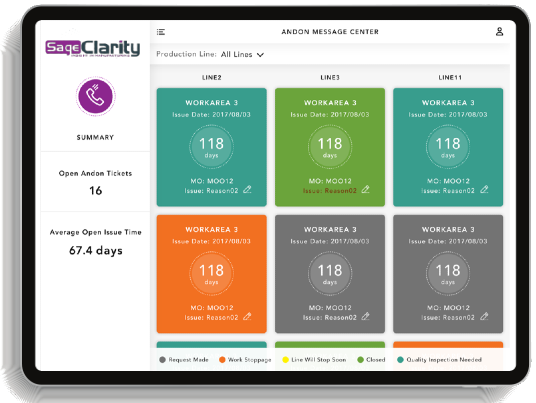

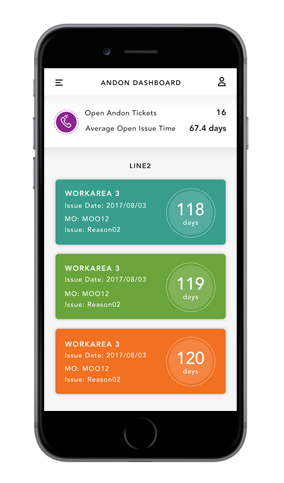

Andon Message Center

Open Andon tickets displayed by priority, color coded by status.

Status Fields Include:

- Andon Type

- Priority

- Work Area

- Production

- Help Type Needed

- Resource Type Needed

Andon tickets can be raised, viewed, and updated, all with just a few taps on the screen. Data can be viewed by line, area, or plant, and is accessible from desktop computers, tablets, or smart phones. Easy custom configuration makes the Andon Message Center customizable for admin users.

Andon Reporting Center

Out of the Box Analytics for:

- Open/Closed Tickets

- Open Ticket Duration Trends

- Average Resolution Time

- Andon Issues Pareto Chart

We can program custom analytics for your specific needs. Date range reporting includes, YTD, MTD, WTD, today, previous week, previous month.

Andon Broadcast Center

Andon system integrated with (MES) applications

Our visible alert system can keep workers and managers in the know, letting them fix issues quickly. The Next-Gen Andon can be integrated with systems such as Epicor Manufacturing Execution Systems (MES). The factory media center can also be linked with your EMI system so production can be seen in real-time by your everyone on the floor.

Features:

- Distribute status on overhead TVs to display alerts on the factory floor

- Provide real-time responsiveness to issues

- Configured to display for a single line, multiples lines, or a designated area

Sage Clarity Next Featured in Automation World

“Next-Generation Andon displays [act] as a way to unite automation and people as a team. New cars, after all, feature lane departure warnings and autonomous braking systems to keep drivers on track, why shouldn’t Andon displays show key-performance indicators and other results to help team members keep the production process on target.”

Andon Lights Integration

Using our API, connect your existing lights with our digital Andon software to get the best of both worlds. Lights alert work floor when issues arise, while the Next-Gen platform sends alerts to operators, engineers, via digital signage and SMS alerts—all while gathering analytics to help improve OEE over time.

ERP & MES Integration

Data is your biggest ally when trying to improve operations. Our Andon software goes beyond traditional systems to log all alerts and compile reports that can be integrated with your MES or ERP systems. You’ll be able to go beyond logging downtime to knowing what line was down and why—across your entire enterprise.

Establishing escalation policies and distribution lists for alerts

Smart Alert System

- Triggered on Initial Andon Incidents

- Automatic Andon Reminders

- Andon Escalations

- Incident Updates

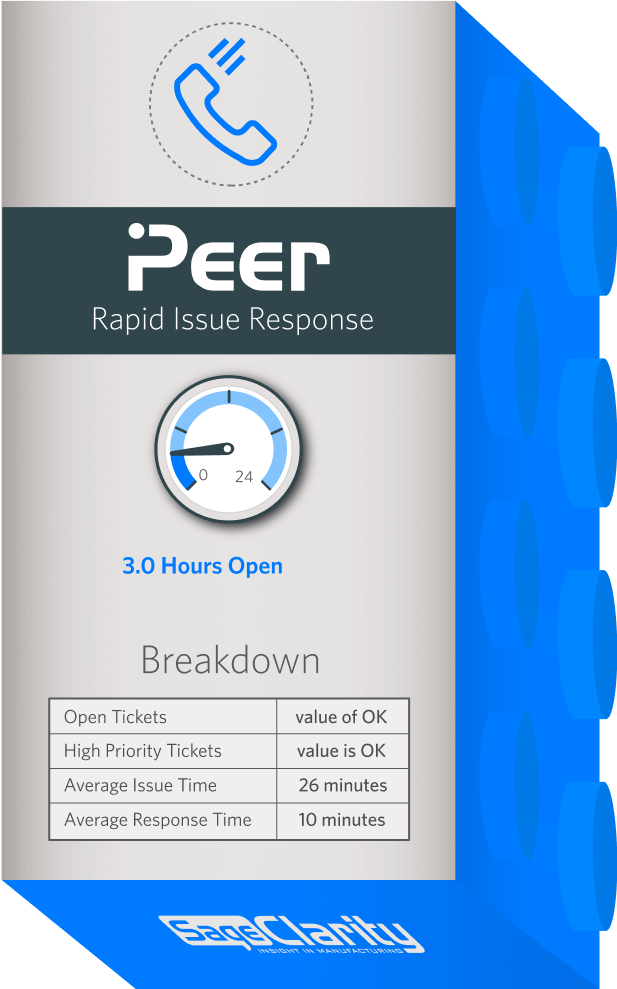

Immediate Response Alert

- Activated by Machines or by the Operator

- Email or SMS Notifications

- Emails will be sent to the appropriate people based on the type of alarm—safety, quality, maintenance—and the location of the alarm

Smart alerts will notify identified key people based on system parameters

Customize your Andon notification settings based on the parameters that you need to track.

Alert Type |

Alert Trigger |

Notification Recipient |

| Line down | Any line is down > 2 hours | Line Supervisor |

| Repeat issues | Downtime for same issue occurs > 3x / hour | Line Supervisor, Maintenance Manager |

| Excessive downtime | Changeovers > 1 hour, PMs > 4 hours | Maintenance Supervisor, Operation Managers |

| Machine specific | Station downtime > 5 minutes | Engineering Manager, Equipment Vendor |

| Quality | Rejects at filler > 1% | Quality Manager, CI manager |

Automate your alerts and improve your Takt time.

Operators are busy. Our Andon tickets are automatically triggered.

Automated alerts to the people that matter

Our Andon system can keep you in the know. With our automated alerts, you won’t have to be on the factory floor to see a production line stoppage.

- Machine automatically triggers Andon events based on certain conditions

- In this example, maintenance acknowledges the event and corrects the issue

- Operator confirms the fix and closes the ticket

- Andon alarms are viewed in the Message Center

Andon Basic Package

- $Andon Basic/mo

- Features:

- Andon Message Center

- Andon Broadcast Center

- Andon Reporting Center

- Email Alerts & Notification

- Issue Tickets with Workflow

Andon IoT

- $Andon IOT/mo

- Features:

- Andon Message Center

- Andon Broadcast Center

- Andon Reporting Center

- Email Alerts & Notification

- Issue Tickets with Workflow

- Andon Production Center

- Automatically Track Production Counts and Cycle Time

- Integrates with MES, CMMS and ERP Systems

Andon Advanced

- $Andon +Lights/mo

- Features:

- Andon Message Center

- Andon Broadcast Center

- Andon Reporting Center

- Email Alerts & Notification

- Issue Tickets with Workflow

- Andon Light Integration