Accelerator Apps to Propel Your Operations

Sage Clarity Accelerator Apps Power Enterprises Around the Globe

Our state-of-the-art app suite will help you modernize data flows from your control system to complex manufacturing systems. Our solutions puts real-time data at your fingertips giving you a complete overview of production lifecycle, from order to product delivery.

Accelerate the delivery of mission-critical KPIs, such as planned versus actual production, unplanned downtime, real-time production quality, and overall equipment efficiency (OEE).

Collaboration • Purpose-Built Analytics • Contextualization

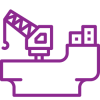

Sending actionable metrics to key stakeholders by providing the Real-Time/Shallow-Dive™ for all levels of an organization. Reduce information overload and get the right information to the right people at the right time.

- Themes of manufacturing metrics grouped into mini-apps packaged in one dashboard

- Top-level scoreboard to give you OEE performance and other KPIs, including production, scrap, downtime, and waterfall analysis

- Cloud dashboard helps you monitor your manufacturing operation from you phone, tablet, and desktop with built-in collaboration tools

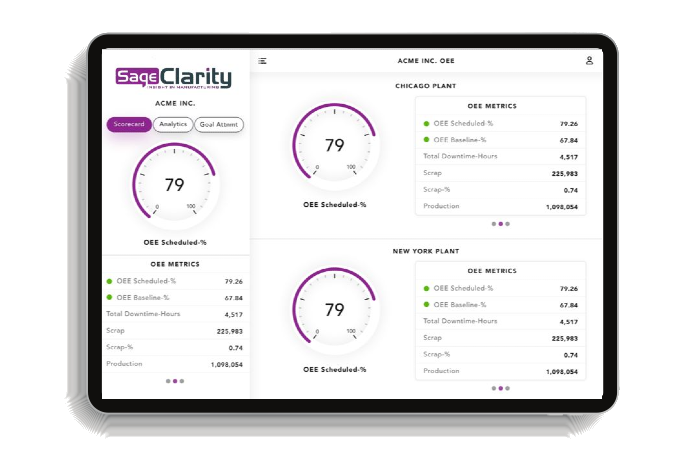

OEE Analytics • Production & Performance Tracking • Real-Time Scheduling

Gain real-time, actionable insights to improve the manufacturing processes of your business – within the individual plant or across the entire enterprise. Improve OEE by reducing downtime, minor stops and quality losses to unlock the hidden capacity of your operations.

- Transform your operations via automated tasks that help you maintain your continuous improvement initiatives

- Gain a strategic advantage through up-to-the-second view of your enterprise, helping you prevent quality issues before they happen and reduce costs

- Reporting that brings data from the production floor to the executive suite to help you make strategic business decision.

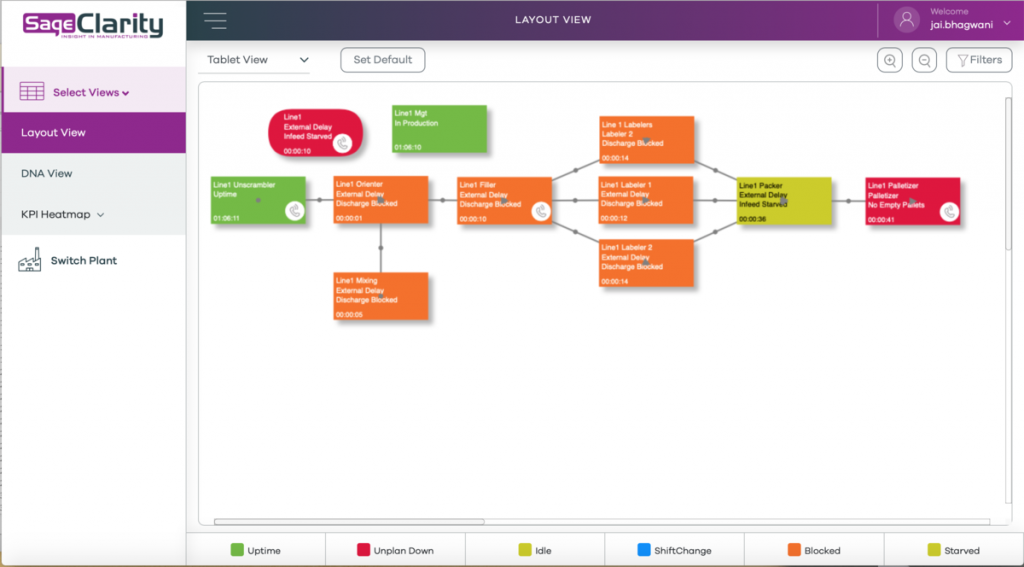

OPC UA Middleware • IIoT Solution • Edge Analytics

ABLE enables transforming IoT data into business systems (MES, SCADA, ERP apps, etc.).

Auto-tagging Business Logic Engine (ABLE) is a lightweight, root-cause IoT solution that leverages OPC UA technology and allows enterprises to simplify control architectures.

- Configurable middleware between automation systems and your MES, SCADA and ERP software

- Edge analytics analyzes device data before its processed, enabling autonomous decision making

- Uses a powerful logic engine to combine line state and line flow to perform an on-the-fly root cause analysis for complex production lines.

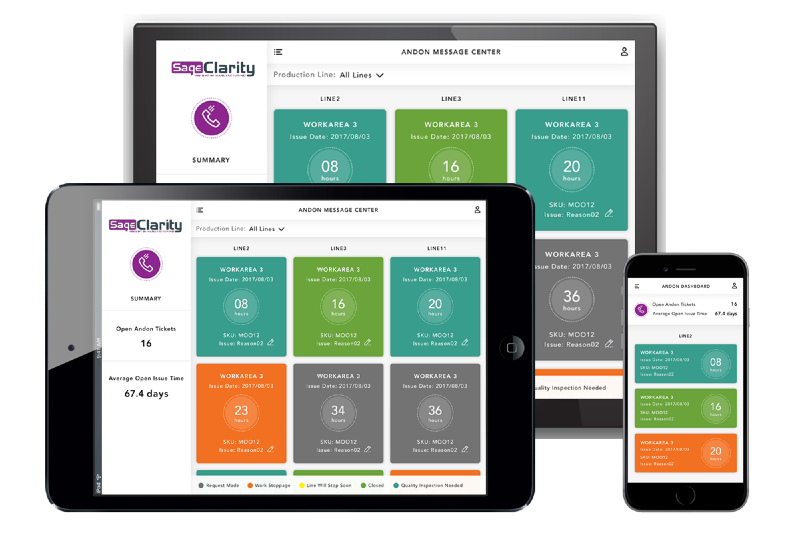

Next-Gen Andon Software

Andon system that integrates with MES Solutions

Our visible alert system can keep workers and managers in the know, letting them fix issues quickly. The next-gen Andon can be integrated with systems such as Epicor Manufacturing Execution Systems (MES). The factory media center can also be linked with your EMI system so production can be seen in real-time by your everyone on the floor.

- Improved communication between operators and engineers through a combined system of digital signage on the production floor with email alerts

- Reduce downtime and better continuous improvement initiatives to improve OEE and Quality

- Role-based alarms notify the right person at the right time based on alarm type and location