Real-Time Global Visibility For the Changing Consumer Packaged Goods Needs

As the number of products manufactured increases alongside the variety of new products being constantly introduced into the marketplace, consumer demand has increased exponentially as well. This increase across the board has caused manufacturers of Consumer Packaged Goods (CPG) such as cosmetics, apparel, cleaning products and pharmaceuticals, to focus on manufacturing efficiently, safely and transparently across the globe.

This ever-changing environment brings new and serious challenged to consider. Whether directly selling to the customer or simply providing components, manufacturers must now meet customer quality standards like never before. They must execute turn-around quickly, offer best per-item price, stand out among the competition and comply with the regulations of a variety of agencies.

Sage Clarity solutions allows your CPG manufacturing process avoid out-of-stock issues, ensure quality control, and improve efficiency to get your product out into the market place quickly.

Our Solutions for the CPG Industry

The Future of Manufacturing Technology

Understanding the importance and value of big data in manufacturing.

Insights from CPG Experts

When Planning Rates Fail Us

Studies show that 30 percent of SKUs in a typical manufacturing facility have at least 10 percent error between the current planning rate used and the ideal, “desired” planning rate. Most manufacturers aren’t even aware of this problem. That’s why frequent, detailed analysis — reviewed more often than annually or even quarterly — are necessary to ensure accurate standard and planning rates.

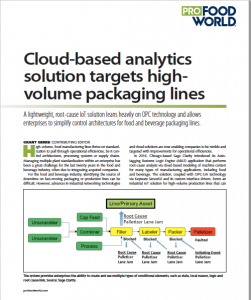

How Our IIoT solution for enterprises simplifies control architectures across packaging lines.

For the manufacturing industry, identifying the source of downtime on fast-moving packaging or production lines can be difficult. However, advances in industrial networking technologies

and cloud solutions are now enabling companies to be nimble and targeted with improvements for operational efficiencies. Our Autotagging Business Logic Engine (ABLE) application performs root-cause analysis via cloud-based modeling of machine centers

for many types of manufacturing applications.