Digital-twin driven smart manufacturing

Most production lines are already gathering data from devices throughout the manufacturing process. Our digital twin platform is a versatile tool that pulls data from your IoT devices to create a visualization of all your data.

What is a Digital Twin?

A digital twin is a representation of a physical system, recreated in software. Digital twin systems for manufacturing are usually built on top of existing IoT systems and used to monitor processes, detect downtime, and predict performance. At Sage Clarity, we design our tools to be lightweight, scalable, and built for maximizing manufacturing quality and efficiency.

Watch a digital version of your production line.

Pause, rewind, and fast forward a visualization of your manufacturing processes. This industry 4.0 technology is the next step to achieving the smart factory of the future. This technology is no longer only accessible to large, multi-billion dollar enterprises. Our digital twin software is fast, lightweight, and integrates easily with your existing MES.

How we build a digital twin with your data.

Machine State Logic

PLC data, IoT sensors coupled with ISA95 standards are used for creating data related to physical processes in your factory.

Integration

Edge data created by state logic is integrated with line flow details and can processed by your MES or OEE system.

Manufacturing Analytics

The raw data is pulled into your analytics platform where it can be visualized and analyzed.

Digital Twin

All the data from the other components are combined into a real-time digital model of your production line.

Our Digital Twin Technology

Powered by ABLE™ – IoT driven root cause analysis

Real-time Digital Twins with Production KPIs

ABLE™ actively monitors your production lines and provides root-cause analysis in real time.

- Line flow modeling determines root cause of downtime

- Mobile views for smart phones, tablets, and desktop HMIs

- See the progression of downtime as it propagates up and down the line

- Analytics available on shop floor HMIs showing Availability, MTBF, and MTTR

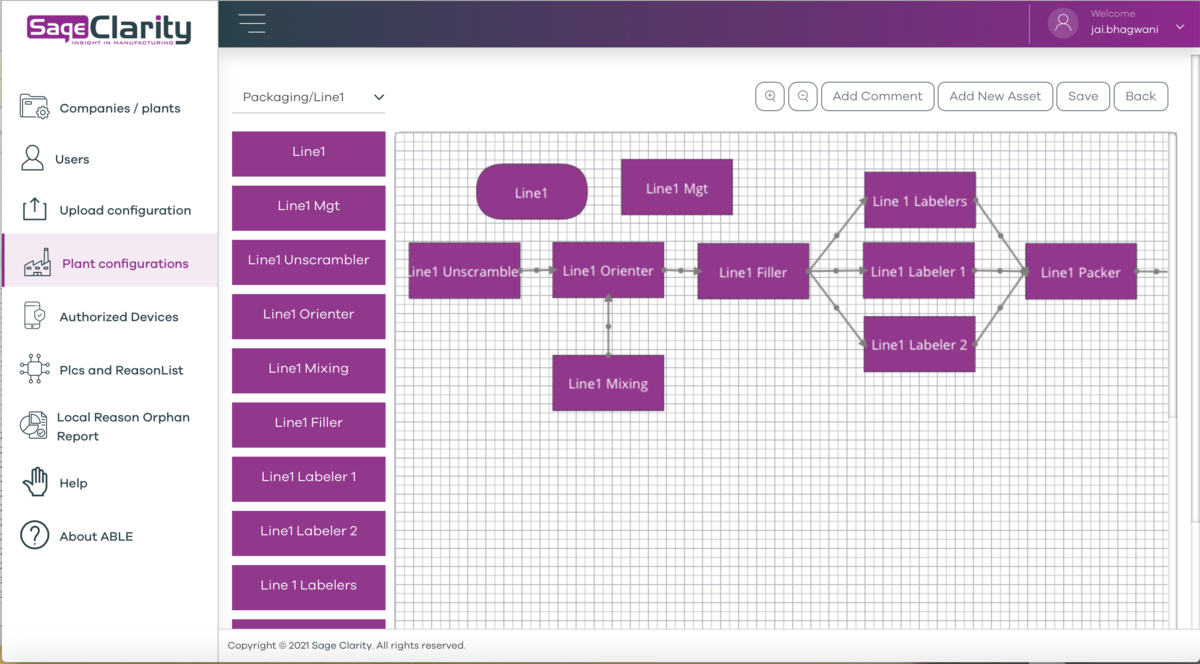

PRODUCTION LINE MODELING

ABLE models machines and production lines with no modification to PLC logic. Line and machine states, counts, root cause are all coalesced in our logic engine and published via Kepware to Epicor Informance, Wonderware, and other MES systems.

- ABLE integrates IoT edge data into business systems—MES, SCADA, and ERPs.

- Production line modeling finds the root cause of downtime so you’ll be up and running quickly.

- Auto-tagging reduces integration costs by 50%, so you can achieve a faster return on investment.

- Reduces PLC Programming for AutoTagging by over 80%

Discover the possibilities our digital twin platform will enable.

Fill out the form to see how our technology can transform your operations.