07 Nov Video Demo: Industry 4.0 Technology

VIDEO DEMO: INDUSTRY 4.0 TECHNOLOGY

See our manufacturing intelligence technology in action

Benefits of Industry 4.0 Across Industries

Machinery

5-10%

Productivity increase as measured by manufacturing costs

Components

4-7%

Productivity increase as measured by total manufacturing costs

Food & Beverage

5-10%

Productivity increase as measured by manufacturing costs

Automotive

6-9%

Productivity increase as measured by total manufacturing costs

Source: Boston Consulting Group Analysis

Our Industry 4.0 Platform

Our technology enables businesses to harness the power of their data to streamline their operations. Create a Control Tower that will help you anticipate risks while optimizing production and supply chain. See how you’re performing in real-time at the line, plant, or organizational level. We have the tools to help you gather, monitor, and analyze your manufacturing activity.

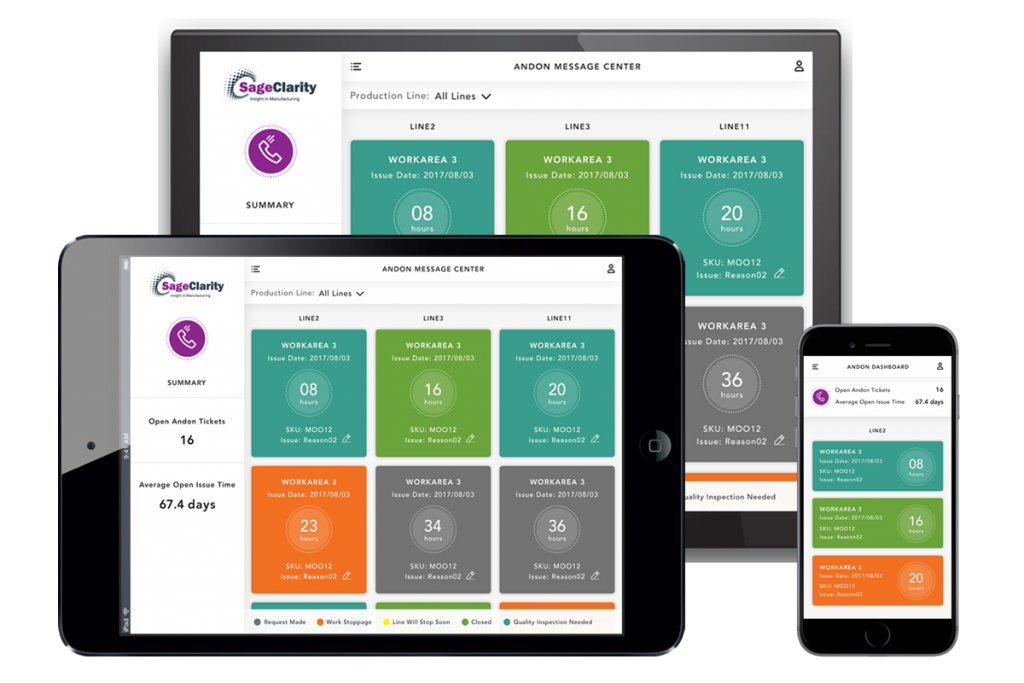

Next gen Andon

Instant Awareness of Production Interruptions

Ensure processes are being carried out efficiently and reliably. Our andon system is a truly next generation technology, essential to improving your manufacturing KPIs.

Features:

- Alerting technology using email, SMS, HMIs and plant floor terminals so no stoppage goes unnoticed.

- Predefined distribution and escalation processes alert only the people who need to know and improve accountability.

- Both automated and operator created alerts ensure your production is operation full steam ahead.

- The Andon reporting center summarizes ticket information by line, area, and status.

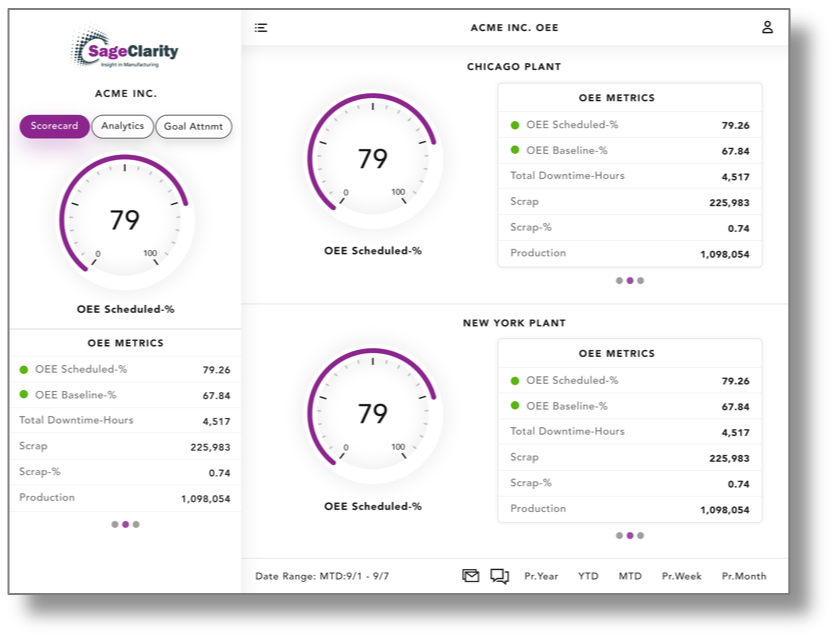

OneView

For Real-time Manufacturing Analytics

Monitor efficiency of individual production lines, plants, or your entire operation. OneView will act as your operations atomic clock, with everyone looking at the same production metrics and working towards the same goals.

- OneView can be installed on top of existing analytics solutions, or stand-alone, to help you aggregate high-level production KPIs

- Engage your employees in supply chain improvement programs with One View’s multi-device compatibility

- Analytics that span multiple business processes and disparate systems. Easily integrate with most major BI systems—SAP, Oracle, Epicor, and Microsoft.

It really appealed to our team that they weren’t going to be inundated with a massive database … It also allows us to talk numbers and data, rather than feelings and instincts and stories.

Peter Gibbons – Chief Supply Chain Officer, Mattel

Swimming in the Shallows, APICS Magazine

ABLE™

Powering IIoT from the Edge

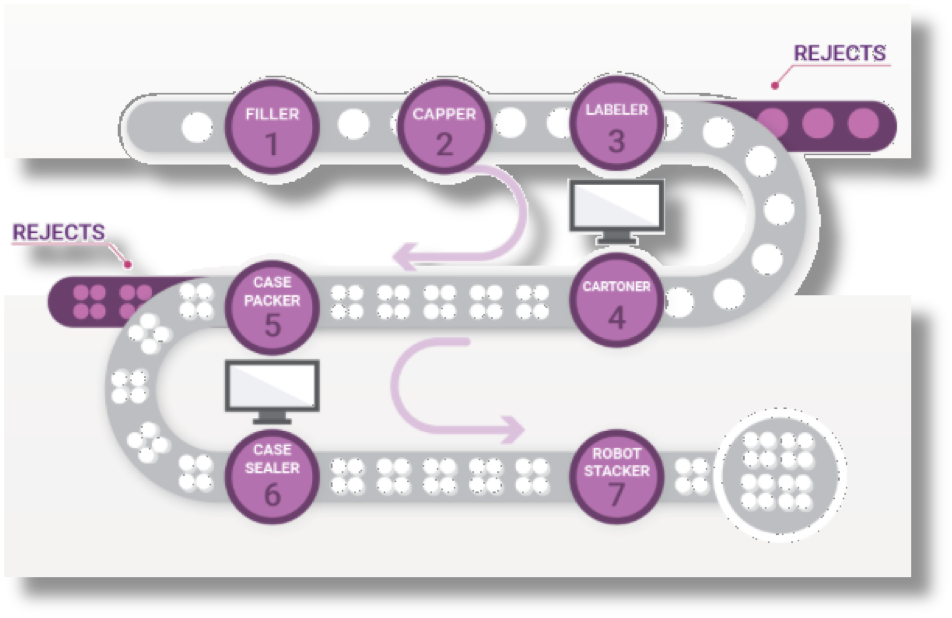

Edge analytics drives root cause analysis that delivers data to your Andon, EMI, and QMS to help you root out issues with productivity and keep your operations lean.

Features:

- ABLE integrates IIoT edge data into business systems—MES, SCADA, ERPs, etc.

- Production line modeling determines the root cause of downtime so you can be up and running more quickly.

- AutoTagging reduces integration costs by 50%, and requires up to 80% less PLC programming, so you can achieve a faster return on investment.