Boost Your Manufacturing Productivity with our IIoT Platform — Now Featured in BCG’s Innovation Center

Industry 4.0 bridges the divide between the digital and physical. Connect your operational technology with production management, manufacturing execution, logistics and enterprise planning systems and gain continuous visibility into the production process.

Advanced manufacturing analytics will help you identify and predict performance bottlenecks in your production, while IIoT edge computing will alert you when downtime happens, and pave the way for quality improvements.

Read our Insiders Guide to Industry 4.0 to learn more about what it is, its history, and different technologies that underpin this paradigm shift.

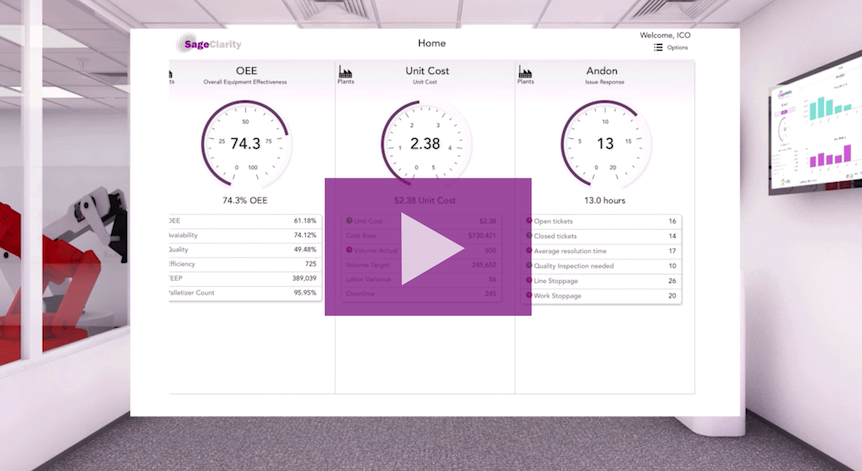

Watch a demo of our Industry 4.0 tech in action.

Benefits Across Industries

According to a Boston Consulting Group Industry 4.0 Study

Machinery

5-10%

Productivity increase as measured by manufacturing costs

Components

4-7%

Productivity increase as measured by total manufacturing costs

Food & Beverage

5-10%

Productivity increase as measured by manufacturing costs

Automotive

6-9%

Productivity increase as measured by total manufacturing costs

Source: Boston Consulting Group Analysis

Showcasing Industry 4.0 with The Boston Consulting Group

Discover the “art of the possible.” Sage Clarity is working with Boston Consulting Group (BCG) to demonstrate our Industry 4.0 technology as part of The Innovation Center for Operations in Wichita State University’s Experiential Engineering building.

Through our partnership with BCG, we provide proven use cases of Industry 4.0 for manufacturing. You’ll interact with a massive touch wall, the Factory Media Center, which showcases our Interactive Production technology.

See a live demo of our IoT platform at BCG ICO at Wichita State University, including:

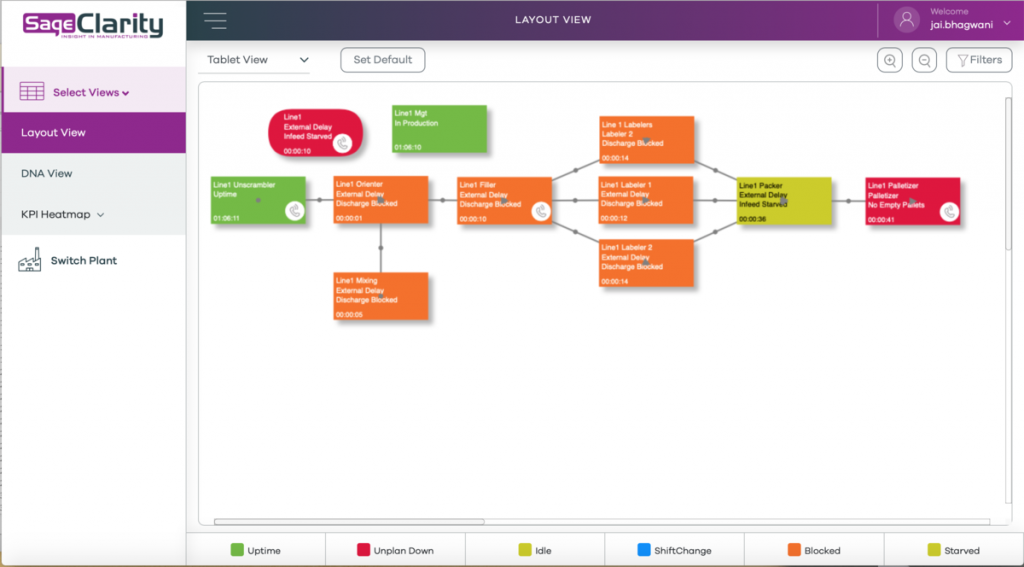

- See how our Next-gen Andon System pushes alerts to the Factory Media Center, shop floor HMIs, and to mobile devices, giving you instant awareness of your production line operations.

- All the manufacturing KPIs you need in one easy-to-use dashboard from our OneView platform.

- Behold the power of edge computing. ABLE™ analyzes data from your production line and delivers root-cause analyses when issues arise, and can even predict potential production issues before they happen.

Our Industry 4.0 Accelerator Apps

Our technology enables businesses to harness the power of their data to streamline their operations. Create a Control Tower that will help you anticipate risks while optimizing production and supply chain. See how you’re performing in real-time at the line, plant, or organizational level. We have the tools to help you gather, monitor, and analyze your manufacturing activity. Now that all our systems are SAML 2.0 compliant, you can access your business systems easier and with more security.

Next-Gen Andon – Process Correction Accelerator

Instant Awareness of Production Interruptions

Ensure processes are being carried out efficiently and reliably. Our andon system is a truly next generation technology, essential to improving your manufacturing KPIs.

Features:

- Alerting technology using email, SMS, HMIs and plant floor terminals so no stoppage goes unnoticed.

- Predefined distribution and escalation processes alert only the people who need to know and improve accountability.

- Both automated and operator created alerts ensure your production is operation full steam ahead.

- The Andon reporting center summarizes ticket information by line, area, and status.

OneView – Reporting Accelerator

For Real-time Manufacturing Analytics

Monitor efficiency of individual production lines, plants, or your entire operation. OneView will act as your operations atomic clock, with everyone looking at the same production metrics and working towards the same goals.

- OneView can be installed on top of existing analytics solutions, or stand-alone, to help you aggregate high-level production KPIs

- Engage your employees in supply chain improvement programs with OneView’s multi-device compatibility

- Analytics that span multiple business processes and disparate systems. Easily integrate with most major BI systems—SAP, Oracle, Epicor, and Microsoft.

It really appealed to our team that they weren’t going to be inundated with a massive database. It also allows us to talk numbers and data, rather than feelings and instincts and stories.

Peter Gibbons – Chief Supply Chain Officer, Mattel

Swimming in the Shallows, APICS Magazine

ABLE™ – Data Collection Accelerator

Powering IIoT from the Edge

Edge analytics drives root cause analysis that delivers data to your Andon, EMI, and QMS to help you root out issues with productivity and keep your operations lean.

Features:

- ABLE integrates IIoT edge data into business systems—MES, SCADA, ERPs, etc.

- Production line modeling determines the root cause of downtime so you can be up and running more quickly.

- AutoTagging reduces integration costs by 50%, and requires up to 80% less PLC programming, so you can achieve a faster return on investment.