Manufacturing Performance OEE Benchmark Data for Fast Moving Consumer Goods

Manufacturing organizations undertake a variety of performance improvement initiatives such as Lean Manufacturing, Six-Sigma, TPM and TQM. Organizations leverage KPIs, including Overall Equipment Effectiveness (OEE) to manage and measure such initiatives.

Epicor in conjunction with Sage Clarity studied over 100 global manufacturing operations worldwide to benchmark performance and correlate over 20 manufacturing KPIs. Researchers used the Epicor Informance Enterprise Manufacturing Intelligence Suite and Clarity advisory services to collect data, derive insight and discover correlations to operational success of tactical and strategic actions.

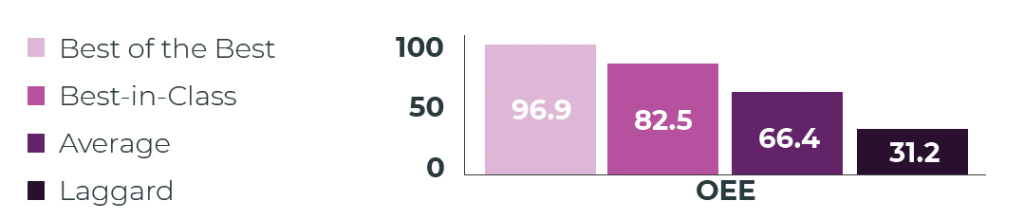

On average, Best-in-Class organizations, exhibit an OEE 2.6x better than Laggards, due to an OEE of 82.5 vs. 31.2:

On average, Best-in-Class organizations, exhibit an OEE 2.6x better than Laggards, due to an OEE of 82.5 vs. 31.2: